We provide High-quality Mining Parts

EXCAVATOR & BULLDOZER UNDERCARRIAGE PARTSOptimal Combination

Fully comply with the RC strength design standard of Japanese mining machinery

- Track Roller: Shafts are made from forged alloy or rolled carbon steel and hardened over 3mm deep to 56-60 RC.

- Carrier Roller: Shafts are made of forged alloy or rolled carbon steel, quenched and tempered heat treated, hardened to 36-56 RC.

- Idler: Idler shells are cast or forged, depending on the design, then heat treated to 48-56 RC and machined to size.

- Sprocket : Are made to OEM fitment specifications and manufactured from cast steel, with the external tooth profiles deep induction hardened in excess of 50RC to provide long service life.

- Segment: Are made to OEM fitment specifications and manufactured by forging, with the tooth profiles being through hardened for extra toughness, better wear resistance and long service life.

12 month/2000hr warranty is not the limit.

- Quality Control ability 95%

- Structural design 90%

- Processing accuracy 85%

- High strength, long life 90%

- Welding Technology 85%

PURSUIT

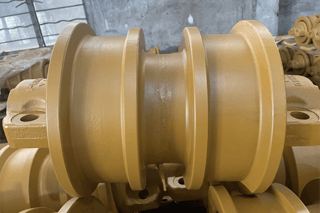

Top Roller

Carrier rollers serve to support the weight of the track chain and distribute the weight evenly across the undercarriage.

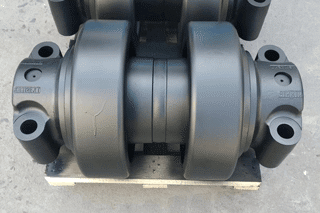

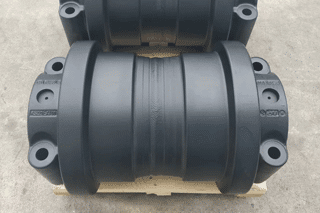

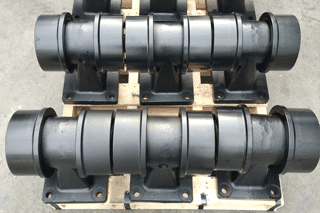

Track Roller

Bottom rollers absorb the machine’s weight and distribute it evenly on the tracks.

Idler

Idler ensures seamless movement and enhances the track’s durability and the complete undercarriage system.

Sprocket & Segment

Sprockets engage with the track chain, propelling the excavator forward.

Excavator & Bulldozer Top Roller

The carrier roller body is forged from two halves of high manganese alloy steel, and then hardened, machined, and welded together by friction or submerged arc.

Specifications

- Material: 40Mn2

- Surface Hardness: 36-56 RC

- Color: Yellow, Black or Customized

- Processing: Forging

- Welding method: Friction or submerged arc

- Applicable machines: Excavator, Bulldozer, or other machines.

- Production range: 6-100 tons model

Specifications

- Material: 40Mn2

- Surface Hardness: 56-60 RC

- Color: Yellow, Black or Customized

- Processing: Forging

- Welding method: Friction or submerged arc

- Applicable machines: Excavator, Bulldozer, or other machines.

- Production range: 6-100 tons model

Excavator & Bulldozer Track Roller

The roller body is forged by the hot die of high-strength alloy round steel, machined and then welded together by friction or submerged arc, and then hardened as a whole, with high strength and good wear resistance.

Excavator & Bulldozer Idler

All Idlers are made to OEM fitment specifications and are pressure tested to ensure guaranteed sealing and reliability

Specifications

- Material: 35#

- Surface Hardness: 48-56 RC

- Color: Yellow, Black or Customized

- Processing: Forging

- Welding method: Submerged arc

- Applicable machines: Excavator, Bulldozer, or other machines.

- Production range: 6-100 tons model

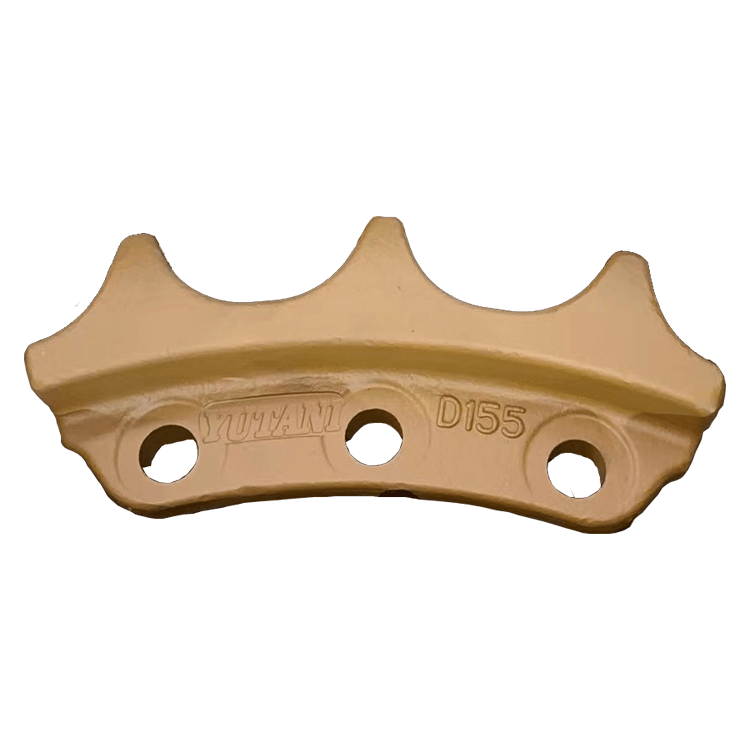

Specifications

- Material: 35MnB or 40Mn2

- Surface Hardness: 50 RC

- Color: Primary color, Black or Customized

- Processing: Forging or Casting

- Applicable machines: Excavator, Bulldozer, or other machines.

- Production range: 6-100 tons model

Excavator Sprocket & Bulldozer Segment

Segments are made to OEM fitment specifications and manufactured by forging, with the tooth profiles being through hardened for extra toughness, better wear resistance and long service life.